Barcelona, June 13, 2017.- The Internet of Things, goods connected to the Internet should today be one of the main tasks to be managed by logistics professionals. We present here studies, analyzes and assessments to understand the impact of IoT on the daily work of the supply chain.

Experts say Internet of Things will be bigger than Internet

The Internet of Things (IoT) will bigger than the Internet itself. That’s the message from Sphera CEO Paul Marushka, who spoke at an Environmental Leader conference this week. What’s driving this?

The main thing is the number of devices that are IoT capable, or things such as smart phones and smart meters. And there are 5.5 million IoT connections made daily, he adds. But the information that the devices gather must be harnessed on a platform, or in the cloud. That data must then become actionable. In the case of environmental managers, for example, it could be used to reduce greenhouse gas emissions.

It is about “analytics or big data, and the ability to mine that information,” says Marushka. “You must then be able to something different than what you do today.”

Consider smart meters, which number 1.5 billion and are used by utilities to gather customer usage information: The proper tools can manage the amount of energy consumption that, in turn, can reduce the level of regulated emissions.

Sensors are at the core of the IoT. Sensors, for example, are used to know if someone is in a room so that the lights can turn on or off. As that technology has become ubiquitous, the cost has dropped: 80% over time.

In manufacturing, IoT can also monitor stoppages, employee behaviors and safety procedures. In transportation, it can monitor shipping, processing and inventory control. The data is in real time so that companies can have relevant information to effect the changes they need. CenterPoint Energy, for example, needs accurate greenhouse gas emissions reports. By using IoT, it has been able to get those reports in two weeks — down from two months. “The trend is not going away,” says Marushka. “It will accelerate. The amount of data that can be collected will have significant environmental effect.”

Taking IoT very seriously for all logistics professionals

Andrew Meola, Content Marketing Producir at Business Insider, has published in BI an interesting analysis on the importance of IoT in the Supply Chain. Here is a summary.

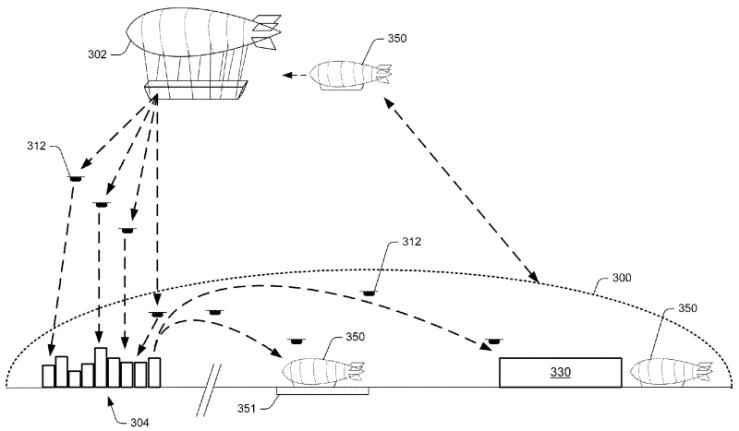

With the advent of IoT, Internet connections now extend to physical objects that are not computers in the classic sense. A connect pallet for example, can tell its owner the whereabouts and condition of their shipment. A connected truck can intelligently predict its own maintenance needs. A connected street light can sense the presence of cars and send environmental intelligence to drivers. These are just some of many intriguing possibilities for IoT in logistics captured in this latest edition in the DHL Trend Research series.

This trend report aims to deepen readers’ understanding of IoT, covering three main issues:

▪ What is the Internet of Things, and why is it a big deal?

▪ What are some of the leading practices and applications of IoT that are generating value across sectors?

▪ What are some of the key use cases for IoT in the logistics industry specifically, and what will be their implications?

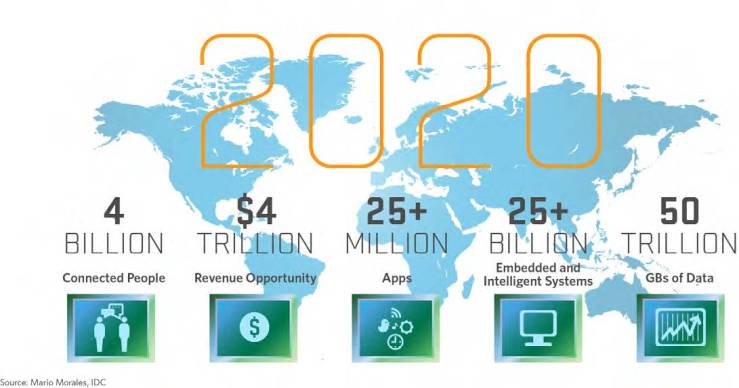

We hope that the report serves as a thought-provoking and inspirational start in understanding the implications of IoT in logistics. As we move from 15 billion connected devices today to some 50 billion by 2020, it is clear that we are only at the beginning of what certainly be an exciting journey for logistics innovation, a journey to connect the unconnected.

One of the biggest trends poised to upend supply chain management is asset tracking, which gives companies a way to totally overhaul their supply chain and logistics operations by giving them the tools to make better decisions and save time and money. Delivery company DHL and tech giant Cisco estimated in 2015 that IoT technologies such as asset tracking solutions could have an impact of more than $1.9 trillion in the supply chain and logistics sector.

And this transformation is already underway. A recent survey by GT Nexus and Capgemini found that 70% of retail and manufacturing companies have already started a digital transformation project in their supply chain and logistics operations.

Asset tracking is not new by any means. Freight and shipping companies have used barcode scanners to track and manage their inventory. But new developments are making these scanners obsolete, as they can only collect data on broad types of items, rather than the location or condition of specific items. Newer asset tracking solutions (which we’ll get into shortly in the next section) offer much more vital and usable data, especially when paired with other IoT technologies.

There are several new pieces of technology that are already changing how logistics companies work. First is active and passive RFID tags, which provide data on items to which they’re attached. The main difference between the two is that passive tags have an RFID antenna and a microchip for storing information, while active tags have their own battery power and can sometimes include additional sensors.

Internet-connected trackers use long-range networks or Low Power Wide Area Networks (LPWANs) to let companies track specific items throughout their delivery journeys. In the same vein, satellite trackers provide location data on an item almost anywhere on the planet, even in areas that do not have cellular coverage.

Bluetooth tags and beacons offer tracking data in smaller, more confined areas, and companies most often use them in retail stores to monitor customer traffic and offer marketing messages to said customers.

Finally, near-field communication (NFC) tags, based on RFID standards, allow workers to use their mobile devices as readers for the NFC tags, which provides an advantage over RFID tags and readers.

Companies and even governments that operate vast numbers of vehicles are more frequently using connected fleet management solutions to make the process more efficient. Much like inventory and warehouse management, these solutions use GPS and other tracking technologies to gather data in real time on the locations and operations of their vehicles. BI Intelligence, Business Insider’s premium research service, estimates that connected fleet management solutions will reach 180 million commercial vehicles in North America, or 90% of the total market, by 2020. This would represent a tenfold increase from 2010.Companies are deploying these solutions in three main ways:

• Physical asset movement and delivery: This includes fleets of largely semi-trailer trucks that transport goods to fulfill consumers’ or business’ orders. These fleets can handle long-haul or last-mile delivery.

• Consumer transportation: This includes governments and businesses that use vehicles to transport people from one destination to another.

• Field-service vehicles: This includes vehicles operated mostly by businesses to transport employees as they perform their job functions.

More Information: